About Scaffolds

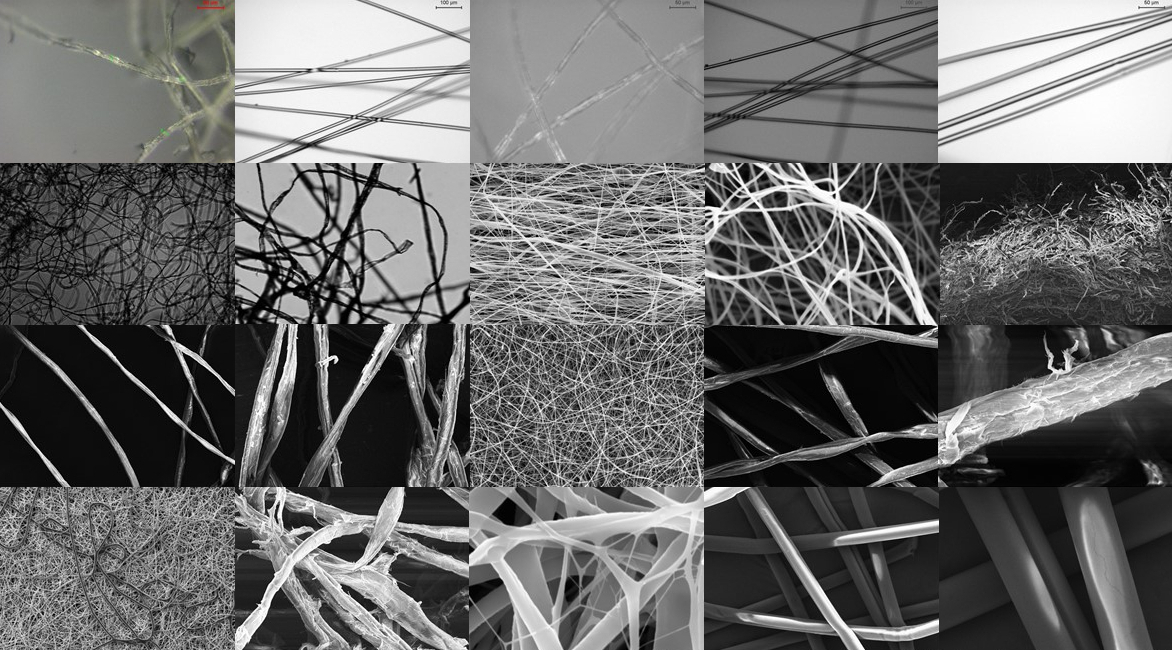

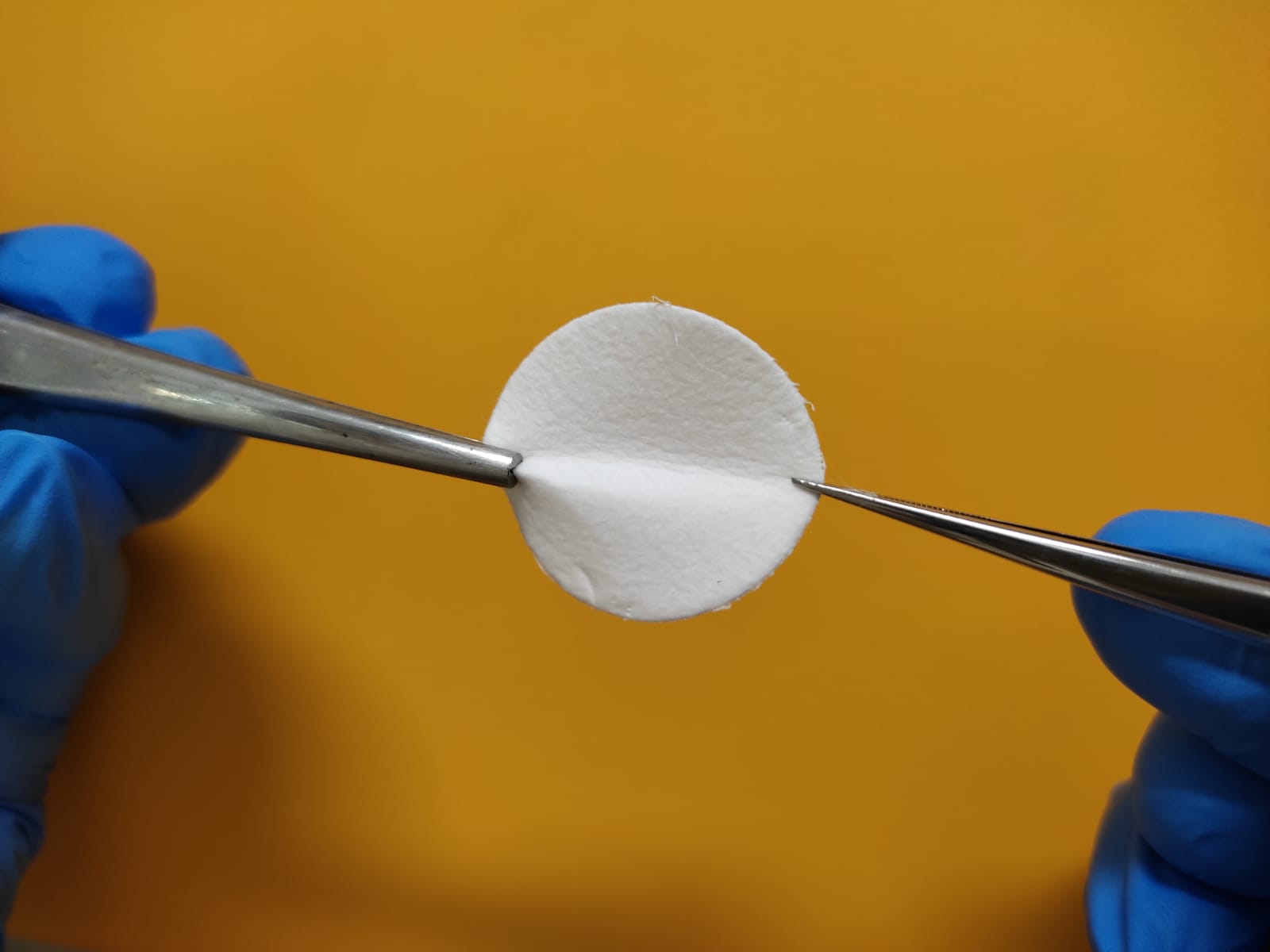

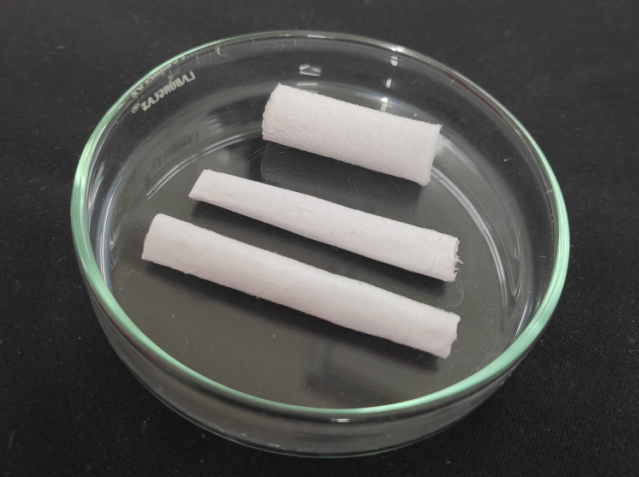

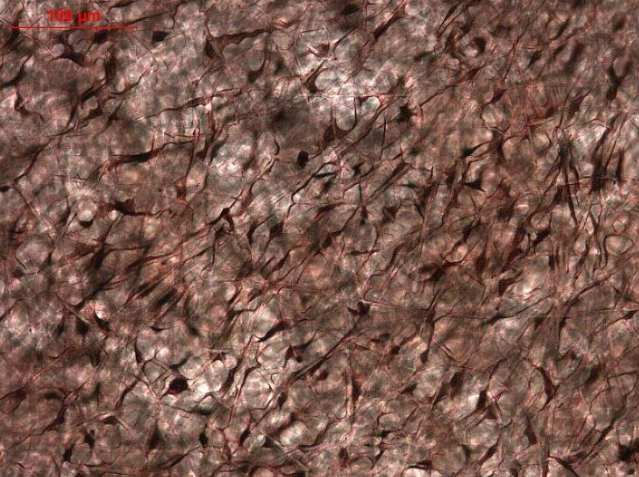

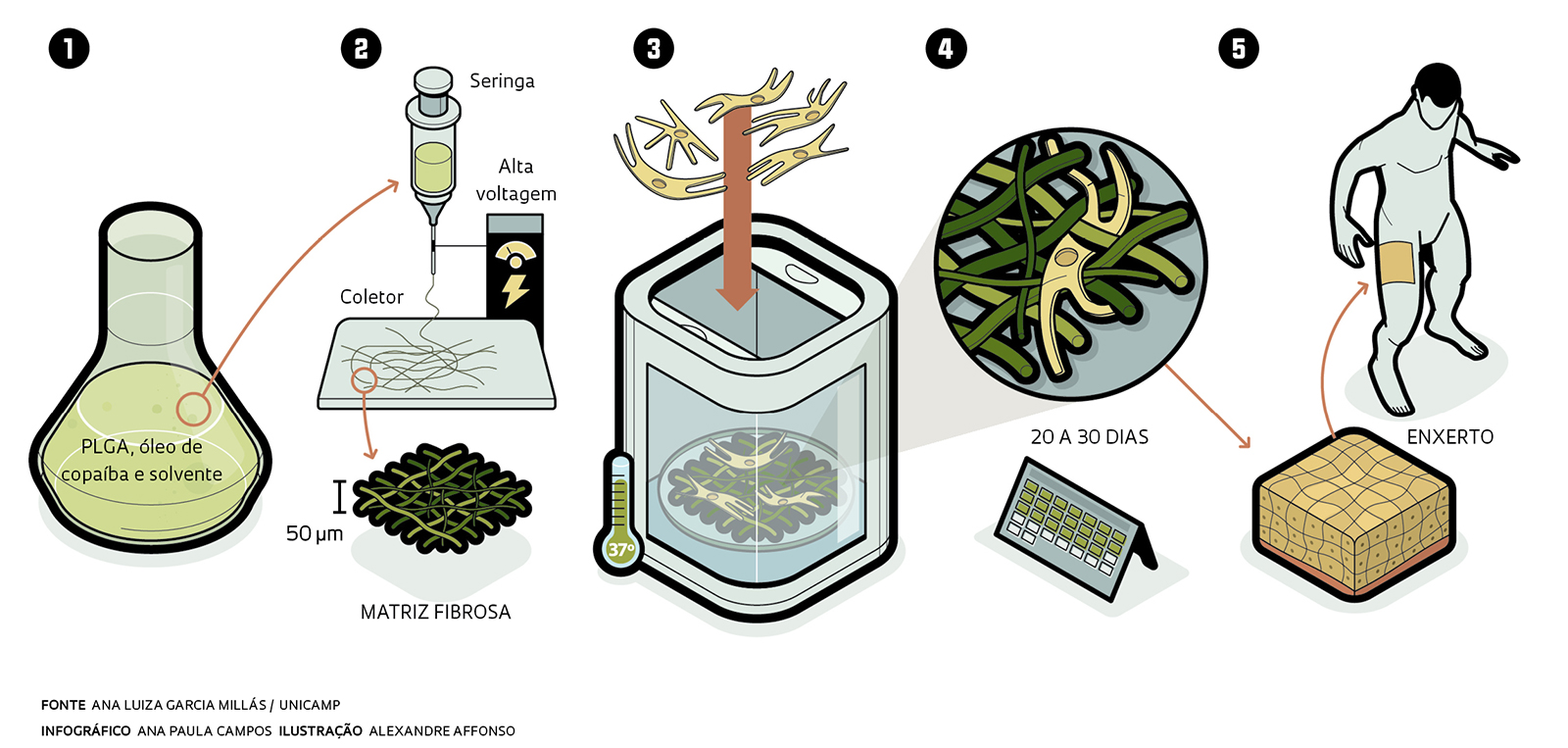

3DBS supplies and customizes scaffolds as per the demand of its customers. Using proprietary electrospinning technology, we use natural and/or synthetic polymers with different degradation rates, thickness and pore sizes to produce fibrous matrices.

With this technology, we generate membranes with high mechanical performance, hydrophilic or hydrophobic, serving various applications in the field of regenerative medicine and tissue engineering.